Cold heading technology of cold heading machine

Source:http://www.yyoucheng.com Author:冷鐓機 Time:2014/8/16 Click:

Cold heading is a forging method that uses a mold to upset (often locally upsetting) metal bars at room temperature. Usually used to manufacture the heads of screws, bolts, rivets, etc. It can reduce or replace cutting processing.

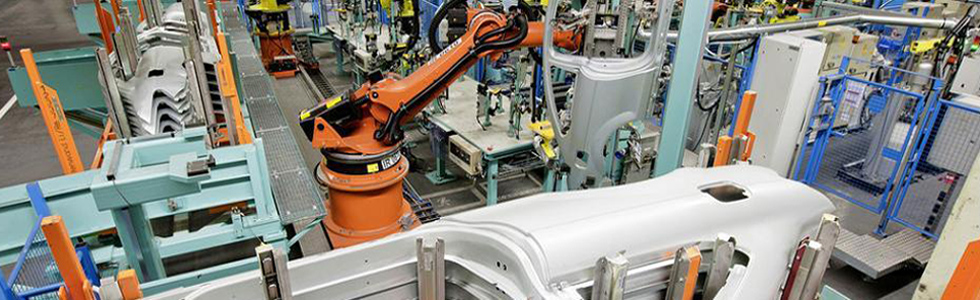

The forging billet material can be copper, aluminum, carbon steel, alloy steel, stainless steel, titanium alloy, etc., and the material utilization rate can reach 80-90%. Cold heading is often carried out on specialized cold heading machines, which facilitates continuous, multi station, and automated production. The cold heading machine can sequentially complete processes such as cutting, heading, accumulation, forming, chamfering, wire rolling, diameter reduction, and edge cutting. High production efficiency, reaching over 300 pieces per minute, with a maximum diameter of 48 millimeters for cold heading workpieces. The bar material is automatically fed into a certain degree by the feeding mechanism, cut into billets by the cutting mechanism, and then sequentially sent to the accumulation and punching stations for cold heading forming by the clamp conveying mechanism. This technology belongs to a type of cold forming, which is a processing method that involves punching, cutting, bending, stretching, etc. of materials without heating. Cold forming processes include cold heading, cold rolling, etc.

The main advantages of cold-formed steel structures are:

1. Compared to thicker hot-rolled steel, cold-formed steel can be processed to accommodate smaller loads and shorter spans.

2. By cold forming processing, it is possible to economically obtain unusual cross-sectional shapes and achieve satisfactory strength to weight ratios.

3. Considering tight packaging and transportation, it is possible to produce nested sections.

4. Under the influence of environmental gravity, there is no expansion, contraction or deformation.

Cold work hardening:

It is the processing of steel at room temperature or below the recrystallization temperature, which can significantly improve strength and hardness, reduce plasticity and impact toughness, and become cold work hardening. The process of heating steel and controlling it above the recrystallization temperature for rolling processing is called hot rolling. The process of making steel below the recrystallization temperature, including at room temperature, is called cold rolling. Hot rolling of steel has good plasticity, is easy to form, and the formed steel has no internal stress, making it easy to process in the following processes. Cold rolling of steel has the characteristic of cold work hardening. Due to its good mechanical properties, many directly used steels use cold-rolled steel

Metal's strengthening index is enhanced during cold deformation.

- 上一篇:Multi station automatic cold h 2014/8/16

- 下一篇:Cold heading _ Introduction to 2014/8/16